Transfer technology DIGIEMME

Di.Gi.Emme S.r.l. is an Italian company that manufactures transfer systems, transfer tools, mechanical and electronic transfer units and complete transfer lines.

The name of Di.Gi.Emme is synonym for innovative solutions that bring savings and joy!

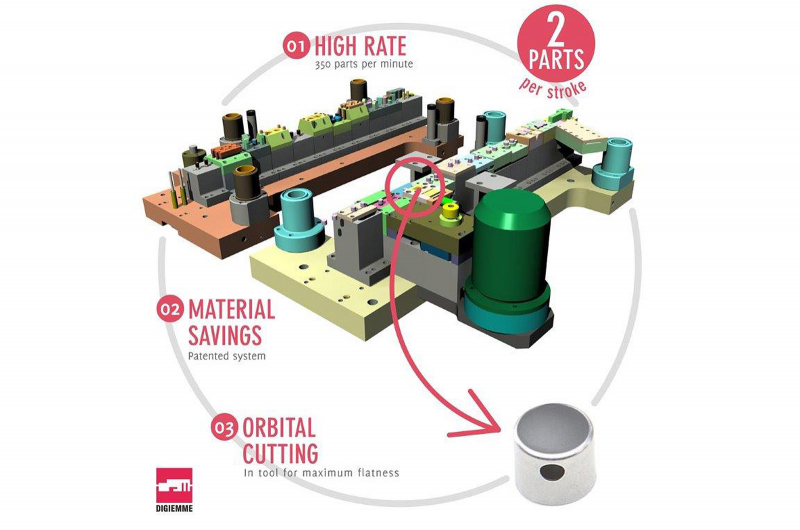

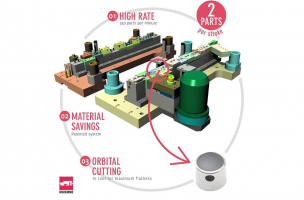

The transfer technology from DIGIEMME means

– less material

– less maintenance

– longer life for your tools

Advantages for transfer technology from DIGIEMME

– significant material saving, up to 20% against the advancing tools

– parts can be rotated and turned over between stations

– more space for punches and dies - strength and durability of tools

– simple and rapid maintenance (individual stations can be independently removed)

– blank optimization for bent-drawn parts using directly in serial stations – needless prototype tools

– the choice of burrs after cutting on either side

– rapid changes on the parts

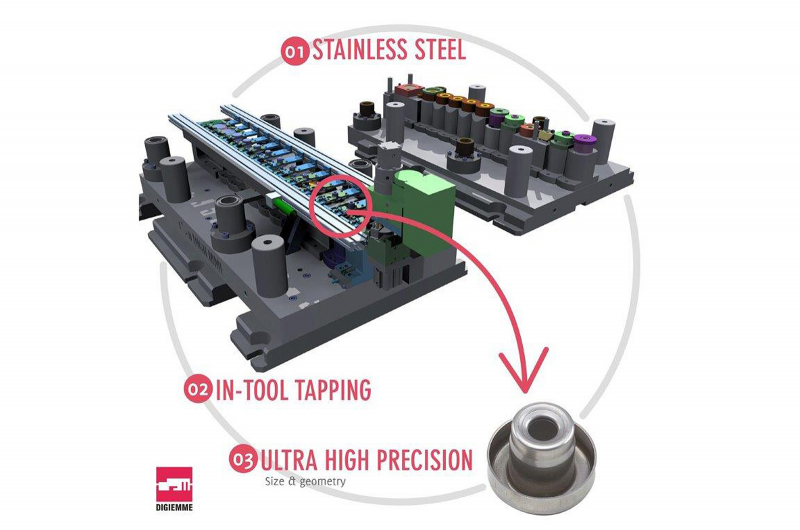

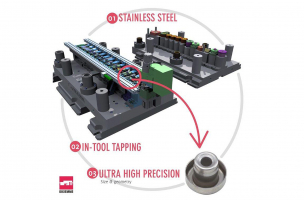

– tapping, welding, washing and other processes directly in operation

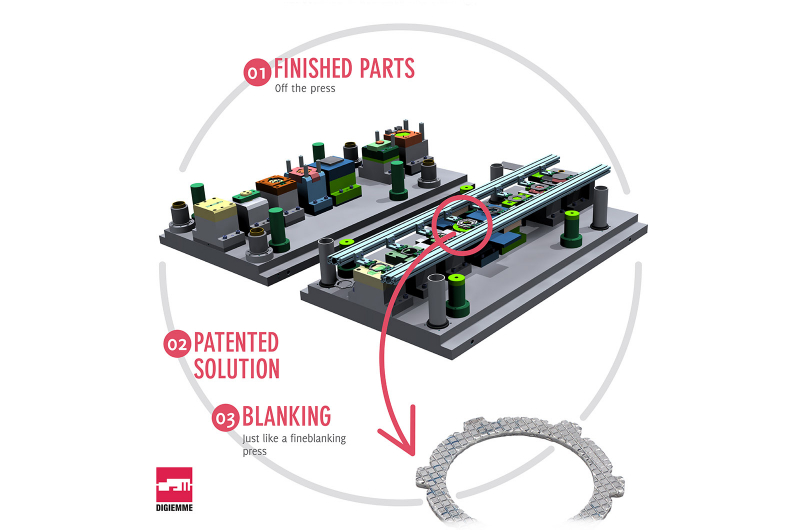

– cutting-edge lines after the final cut, without secondary operations, outstanding quality cut as Fineblanking

A turnkey solution

Cooperation between customer and our experts also means determining the optimal design of the stamping part, to achieve high quality and reliability of the process.

Printed catalogs available at

Phone: +420 577 607 315

E-mail: office@konturatools.cz

Links

DIGIEMME official website (link)

Catalogs for download

DIGIEMME Transfer Tool Brochure, English (PDF)

DIGIEMME Transfer Tool Brochure, Germany (PDF)

About DIGIEMME company

Di.Gi.Emme has been in the field of transfer stamping and cold metal forming technology since 1974. We design and manufacture transfer systems and tools, turnkey lines, mechanical and servo drives to transfer parts from operation to operation for any industry. We also supply finished moldings, including the production of final components.

E-mail

info@konturatools.cz

E-mail

info@konturatools.cz

Contact us

+420 777 945 957

Contact us

+420 777 945 957