Strip, parts and wire straighteners, unwinders, unwinding and winding equipment SOPREM

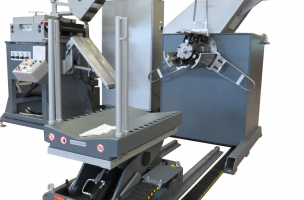

Straightening of input materials before the stamping process has several reasons. After using the straightening machine Soprem, I will have even parts, prolong service life of my tools and ensure the process stability. Then it does not matter if I am at the beginning or at the end of a coil. The material so levelled, when using the precise straightening machine SOPREM, i.e. deprived of internal tension from primary production, is prepared for further processing. With its technical set-up of the sheet metal and part straightening machine SCHUBERT or SOPREM, SOPREM guarantees that stamping becomes a reliable process. The straightening machines SCHUBERT are well-known mainly from the laser technology where parts after laser, but also before laser, are levelled by using 19-roll straightening machine. Wire straightening or rolling or sheet metal unwinding and winding are also included in the programme of the company SOPREM. The programme for the Soprem unwinders brand includes a wide range of devices. The unwinders are produced for unwinding a strip with thickness of 0.05-12 mm and for width of 800 mm. The unwinders, also revolving ones with integrated straightening machines, have loading capacity up to 4 tons.

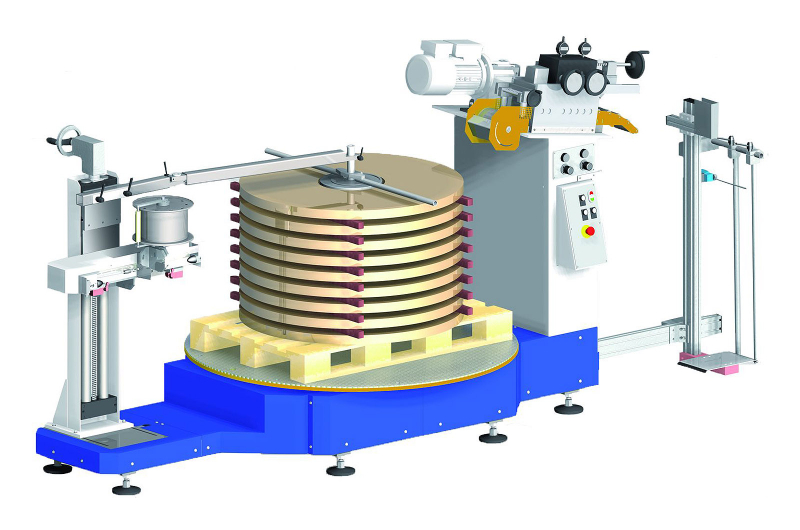

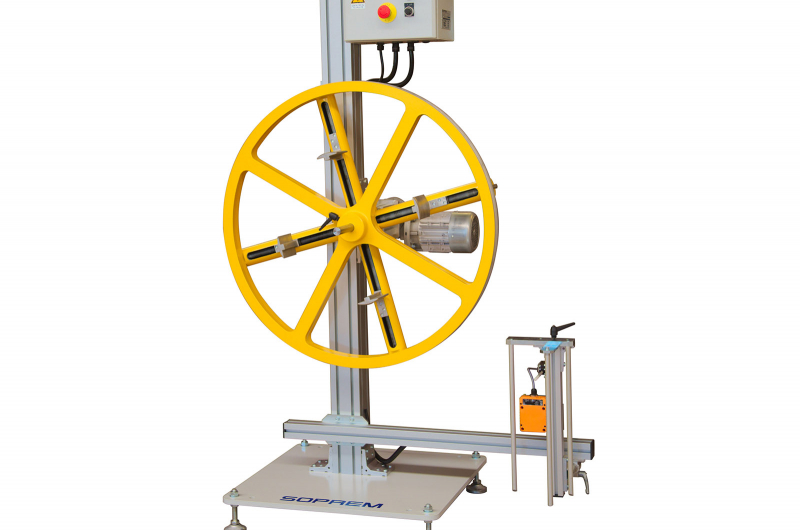

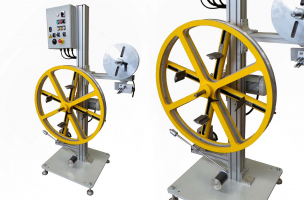

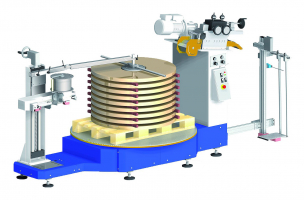

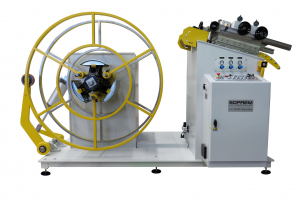

Unwinders SOPREM

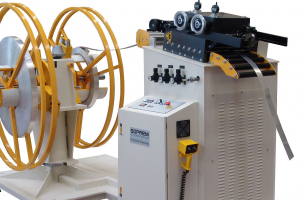

Unwinding of materials has its important role in the stamping process. Like stamping tools, unwinders and winders also have to fulfil their role. The unwinders of the company SOPREM will arouse your interest with their failure-free and maintenance-free operation; then unwinding can be performed even under the most difficult conditions 24 hours per day. The unwinders and winders SOPREM have a lot of designs, both in tonnage and horizontal or vertical designs. The horizontal unwinders enable to load very quickly the whole palette with several coils at one time on the unwinding plate, thus reducing considerably time necessary for change-over of a coil. Thus, the whole process shortens non-productive times to the minimum. The winders SOPREM can have both revolving design and simple design with many options. According to the customer’s requirement, it is possible to equip the winders with paper unwinding and a brake. Welding of input material-strip plays its role in increasing productivity in large-lot production of stamped parts. The welders will enable to weld ends of a coil so that a new coil would not need to drive again into a tool. According to its complexity, driving again into a tool takes up to 30 minutes. During this time, a considerable number of stamped parts can be welded with a welded coil. This contributes very much to utilization of time of the machine. Thus, the welder shortens replacement and driving of a new coil to the minimum and eliminates risks of a stamping tool failure that is enormous just during driving into a tool. The welder from the company Soprem can weld practically all common materials designed for stamping, of course also stainless steel and copper. The welders are able to weld materials with thickness of 0.08-2 mm with a belt with width up to 300 mm.

Printed catalogs available at

Phone: +420 577 607 315

E-mail: office@konturatools.cz

Links

Soprem official website (link)

Catalogs for download

General overview of SOPREM products - German (PDF)

General overview of SOPREM products - English (PDF)

SOPREM unwinders - German (PDF)

SOPREM unwinders - English (PDF)

SOPREM braces - German (PDF)

SOPREM braces - English (PDF)

About SOPREM company

Since 1961, the name SOPREM has been characterized by customer orientation, reliability and accessibility. Customer needs are what drive our 30 employees.

E-mail

info@konturatools.cz

E-mail

info@konturatools.cz

Contact us

+420 777 945 957

Contact us

+420 777 945 957